Power Curber 5700-C: Features

At Power Slipformers we believe in keeping things simple. Our engineering and design are based around providing customers with an easy to operate, reliable, and productive machine. This design strategy is evident throughout the Power Curber 5700-C.

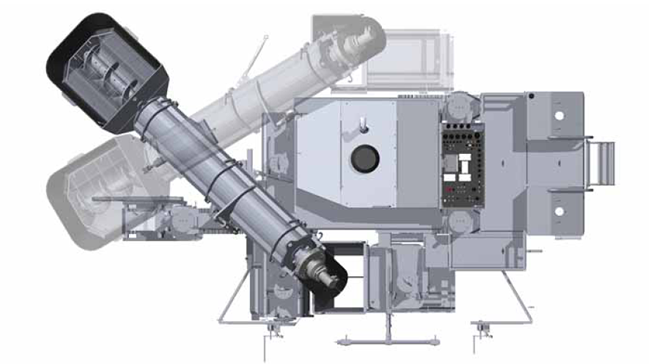

Compact Design:

The 5700-Cís compact design allows operators to get in and out of tight spots like car park corners, islands and cul-de-sacs. The machine transports at just 2.59m and does not require a low-boy.

Visibility:

The operator has an excellent view of concrete as it exits the mold, allowing you to make adjustments immediately to minimize handwork behind the machine. The operator also has good visibility of all activity around the machine.

Stability:

The low center of gravity makes the machine stable on rough subgrade and when loading and unloading.

Front Track Steering:

In keeping things simple, the 5700-C turns tight radii by steering the front track only, eliminating the complication of coordinating all three tracks together. However, all crawler steering is available as an option.

Auger Conveyor

After years of building machines with conveyor belts and dealing with their inherent problems like ripping in the middle of a pour and the concrete splatter they cause, Power Curbers introduced the auger conveyor in 1994.

It is the best change weíve made to a machine.

The direct drive, high torque auger:

- Moves volume concrete faster

- Keeps the machine cleaner

- Continues the mixing process of the concrete

- Holds a cubic yard (3/4m3) of concrete which is beneficial in radius and cul-de-sac work

- Conveys concrete regardless of the incline angle of the conveyor. The unique ability of the charge hopper to be positioned in front of the machine, allows a concrete truck to run lined up in front of the machine enabling you to pour in a single-lane of traffic.

- Large capacity charge hopper, low to the ground, allows for easy discharge from

ready-mix truck. - Hydraulically adjustable tilt and slide, and manual pivoting – position it just like you need it for today’s pour.

- Long-lasting, segmented cast flighting lasts much longer than a belt.

- Delivers concrete up to 1.5m3 per minute.

- The enclosed housing contains the concrete, keeping the machine clean and continues the mixing process all the way to the mold hopper.

- Lid opens for cleaning.

- Discharge chute is adjustable, further allowing for positioning flexibility of the auger.

Hydraulic Adjustable Offset

The mold mount on the 5700-C moves hydraulically giving you the ability to raise, lower, and side shift your mold quickly and easily. With 610mm of horizontal movement and 406mm vertical, the mold can be lowered into a trench for rehab curb or for pouring adjacent to existing pavement.

At catch basins, the machine never leaves the stringline and the mold can be positioned within inches of the obstacle reducing labor intensive tie-in work. The offset also gives you greater versatility when setting up on jobsites that may have obstructions like manhole covers, planter strips, and uneven subgrade.

Trimmer

The stout 1.07m wide carbide-tooth trimmer handles the toughest of subgrade minimizing your dependence on the grading contractor. Ideally the trimmer cuts 25-50mm of subgrade, but is capable of trimming up to 150mm in extreme situations.

The trimmer also hydraulically side shifts 2.03m giving you the ability to trim for a 1.5m radius or to move the trimmer under the machine and out of the way when not in use. With 406mm of hydraulic vertical movement, the trimmer can lift over catch basins and other obstacles.

Cuts grade allowing you to pour without wasting concrete or running the mold into high spots.

- Allows the mold and the soil to intersect creating a perfect seal.

- Extensions available for trimming up to 1.98m wide.

- Choice of carbide teeth – bullet or chisel point – depending upon your soil type and conditions.

- Vertically and horizontally adjustable, independent of machine positioning. Adds flexibility in radius work, rehab, and sidewalk.

- Moves out of the way when pouring barrier or when steel is fed into the mold.

Pour on the Left and Right Side

The standard setup of the 5700-C is for left side pouring. If your work involves highway projects where you must pour with traffic, the dual side pouring option is a huge plus. Changeover from side to side is around 3 to 4 hours.

Choice of Control Systems

In order to keep things simple for your operator, we've kept analog controls as the standard for many years. On the 5700-C, we offer our Smart Ampô control system which combines the simplicity of analog with the added benefits of a digital controller.

The Smart Ampô system offers the operator more accuracy and greater feel when setting sensitivity, without complexity. The system performs self diagnostics, automatically shuts off sensors if they leave the stringline, and has an easy to read digital display.

Our optional controller, the fully networked digital control system gives you the added benefits of an advanced graphic display and auto-slope control on the go when transitioning from in-flow to out-flow. The network system also features cruise control, which can contribute to a smoother finished product. Best of all, the system is 3-D ready, when 3-D is ready for your jobsite.